- Guizhou Boda Packing Co., Ltd.

- Main products: block bottom valve sack, pp woven corn bag, rice bopp bag, corn pp woven sack, jumbo woven sack, pp woven sack, pp woven ton bag, fertilizer bopp bag, pp woven bag, STARLINGER cement bag, AD STAR bag, Block bottom valve bag, ad*star cement bag, block bottom valve bag

Home > Blog > BOPP laminated woven bags, Jumbo Bags, HDPE/PP woven fabrics bags, Tarpaulins and Laminated Rolls

Company News

We are manufacturer, wholesaler and supplier of various packaging material like polypropylene woven sacks, pp woven sack bags, laminated bags, printed LDPE bags,

HDPE Woven Bags, BOPP laminated woven bags, Jumbo Bags, HDPE/PP woven fabrics and bags, Tarpaulins and Laminated Rolls.

PP sacks fabric consist of PP plastic threads that are woven together for creating a durable & flexible material whereas Polyline Woven Sacks

are bonded together instead of woven. To bond them together plastic fibers are fused via heat and pressure. We using only high-grade raw material to produce fabric.

We offer a wide range of woven polypropylene sacks in different colors and sizes.

These woven sacks are made from high quality material ensuring durability of it.

PP woven sacks are widely use and the cost-effective packaging solution for various industries like cement, fertilizers, chemicals, salt, food grains, oil seeds and many more.

rice, sugar, beans, salt, flour, fertilizer, feed, sand, and cement.

There are various types of bags made out of PP sack and with or without lamination. Also, it is popular choice for bale wrapping and rain protection in the form of Tarpaulin.

We have word-class manufacturing facility in terms of Factory Building, and Plant & Machinery. Our production capacity is 200 tons per month.

We are able to meet bulk orders and service the specific requirements of our customers.

We would like to invite our valuable and potential customers to have a close look to our production line.

We have one Tape extrusion plants which are supplemented with 72 Circular Weaving Looms and other Quality Control Equipmentâs.

In Finishing division â we have Automatic Cutting & Printing Machines and Stitching Machines.

Varieties of PP woven sack fabrics:

Plain PP woven sack fabric

Laminated fabrics

Sack with liner

Printed sacks

Key Features:

PP woven sacks are lighter weight

Less expensive

Fully recyclable & reusable

Having greater bursting strength

Resistance to tearing

Environment friendly

Specification of PP woven sacks:

Material: PP

Capacity: As per requirementsWidth: Circular Form â 30 cm to 90 cm (12â³ to 36â³)

Denier: Up to 1500 Denier

Size: 25 cm to 200 cm

Length: As per requirements

Mesh: 8Ã8 to 12Ã12 or as per requirements

PP Fabric: Laminated/Coated or Uncoated fabric

Colors: As per requirements

Printing: Up to 6 colors on one or both sides

Weight: 40 GSM to 140 GSM and above

Lamination: 15 Micron to 50 Micron

Gusseting: Gusseting on each side (as per requirement)

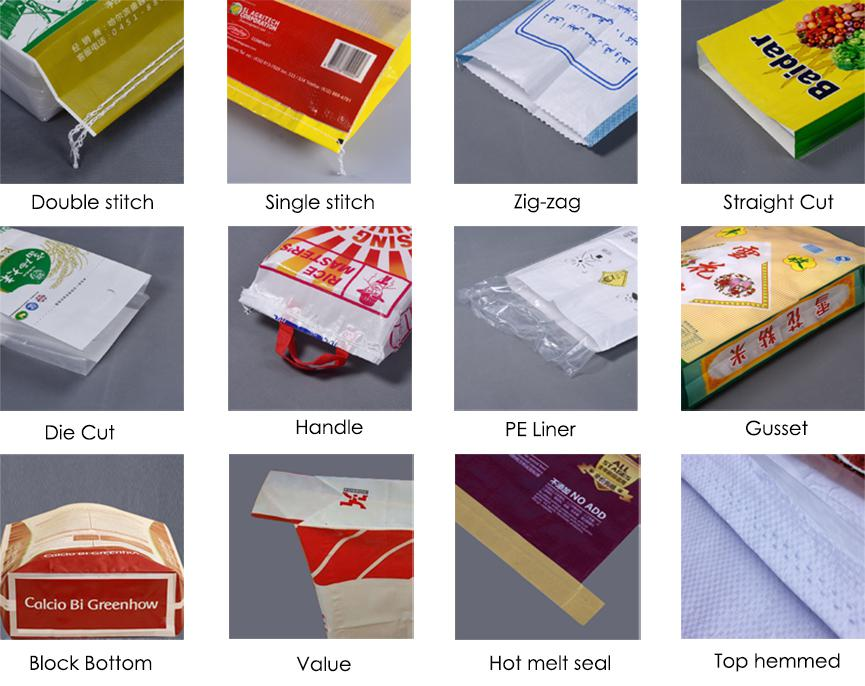

Bag opening: As per required

UV stabilization: As per requirements- 200 to 1600 hours

Packing: Rolls up to 5000 meters or as per requirements